MSE 08 Thermoelectric Generator Experiment

- Jinwook Chang

- Feb 3, 2024

- 8 min read

This experiment builds a small thermoelectric generator using a Peltier module to show how temperature differences can be converted into electricity, highlighting the Seebeck effect, performance limits, and applications from waste heat recovery to space exploration.

Introduction

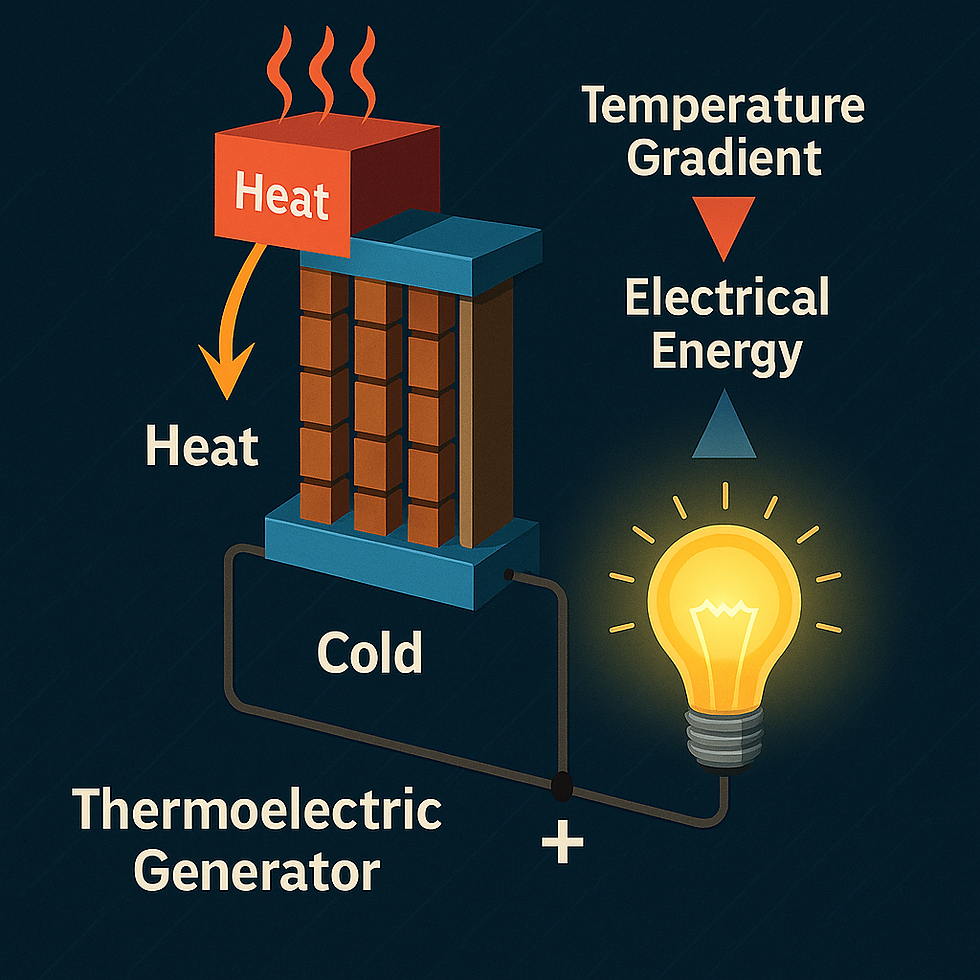

Thermoelectric generators are devices that are capable of directly converting heat energy into electrical energy. Unlike other conventional power generation systems that rely on mechanical motion, combustion, or electromagnetic induction, thermoelectric generators utilize differences in temperatures to achieve energy conversion. Their operation is based on the Seebeck effect, which was discovered by Thomas Johann Seebeck in 1821, which describes how a voltage is produced across two conductors or semiconductors when they are exposed to a temperature gradient. This principle makes thermoelectric generators uniquely valuable for applications in which other energy sources are impractical, such as in deep space missions, waste heat recovery, or wearable electronics. By emphasizing the contrast between traditional mechanical energy conversion systems and solid-state thermoelectric modules, this experiment can demonstrate why these forms of electricity conversion are unique.

Conventional systems often involve turbines, moving parts, and mechanical wear, all of which introduce inefficiencies and maintenance challenges. In contrast, thermoelectric generators are silent, reliable, and scalable. They are particularly suitable for environments where other technologies might struggle, such as deep-sea exploration, polar research stations, or deserts. Furthermore, as global energy demands grow and concerns about climate change grow, the ability to harvest energy from heat, which is an abundant and often wasted resource, becomes increasingly important and sought after. This places thermoelectric generators as a technology capable of leaving a long-term social impact.

This experiment demonstrates how a small thermoelectric generator can be constructed and tested using commercially available Peltier modules. Peltier devices are normally used for cooling; however, when the flow of heat is reversed, they can act as thermoelectric generators. By applying heat to one side of the module and maintaining a cooler temperature on the other side, electrons within the semiconductors migrate, creating a measurable electrical output. The simplicity of this system allows us to directly observe thermoelectric conversion.

Aim

The primary aim of this project is to design, build, and evaluate a small-scale thermoelectric generator using a Peltier module. This experiment aims to:

Investigate the relationship between the temperature difference across the module and its voltage/current output.

Analyze the efficiency and performance limitations of the module under different cooling conditions.

Understand the potential of thermoelectric generators as renewable energy systems for real-world applications, including space exploration, the automotive industry, and wearable technology.

Context

Energy efficiency is a growing priority in the 21st century. Globally, industrial processes, transport systems, and energy production facilities waste large amounts of heat, often dissipated into the surrounding environment.

Thermoelectric generators offer an opportunity to harvest and utilize wasted heat and convert it into useful electricity. Unlike solar or wind power, which depend on environmental conditions, thermoelectric generators require only a temperature gradient, which can often be guaranteed in industrial settings because all technology releases heat as a byproduct. In consumer electronics, researchers are already experimenting with modules that harvest heat generated by laptops or smartphones to extend battery life. The adaptability of thermoelectric generators to both high-tech and low-resource environments demonstrates their wide-ranging application. The difficulty regarding thermoelectric generators is not in proving their usefulness, but in overcoming material and cost limitations that hinder widespread adoption.

The reliability of thermoelectric generators has been proven in space exploration. Radioisotope thermoelectric generators have powered NASA’s Voyager probes since 1977 and have been continuing to provide electricity after more than four decades in the harsh environment of space. These devices operate by placing a heat source, which is usually the decay of plutonium-238, on one side of the module, with the cold of space providing the gradient. This long-term reliability, achieved with no moving parts, highlights the potential of thermoelectric generators for applications on Earth, particularly in remote or inaccessible areas.

Theoretical Background

The operation of a thermoelectric generator is explained by thermoelectric phenomena, of which the Seebeck, Peltier, and Thomson effects play important roles.

The Seebeck effect is the most directly relevant. When a temperature gradient exists across a semiconductor or metal junction, charge carriers diffuse from the hot side to the cold side, producing a voltage.

In addition to the Seebeck effect, two related phenomena complete the thermoelectric effect: the Peltier effect and the Thomson effect. The Peltier effect is the reverse of the Seebeck effect – when a voltage is applied across a junction of two materials, heat is either absorbed or released at the junction. This is the principle behind Peltier coolers. The Thomson effect, which was discovered later, describes how a current flowing through a material with a temperature gradient will result in heating or cooling along the conductor. Together, these three effects explain the dual use of modules as both coolers and generators.

Materials

Peltier module (e.g., TEC1-12706, available online or at electronics stores).

Heat source:

Candle, small gas burner, or hot plate.

Cooling source:

Ice pack, cold water, or a heatsink.

Heat sink (optional but recommended for the hot side):

Aluminum plate or small heatsink for better heat distribution.

Wires:

Insulated wires for electrical connections.

Multimeter:

For measuring voltage and current output.

Load device:

LED, small motor, or a low-power device to demonstrate generated electricity.

Thermal paste (optional):

To enhance thermal contact between the Peltier module and surfaces.

Non-flammable base:

Ceramic tile or metal sheet to place the heat source and module.

Procedure

Step 1: Set Up the Peltier Module

Identify the Sides:

A Peltier module has a hot side (label side) and a cold side (unlabeled side). When a temperature difference is applied, it generates electricity.

Enhance Thermal Contact:

Apply a thin layer of thermal paste to both sides of the Peltier module to improve heat transfer.

Step 2: Position the Module

Prepare the Base:

Place the Peltier module on a non-flammable surface with the hot side facing down (toward the heat source).

Add Heat Sink:

Attach a heat sink or aluminum plate to the cold side. This will help maintain a temperature difference.

Step 3: Create a Temperature Difference

Heat the Hot Side:

Place a small candle or heat source beneath the hot side of the Peltier module. Ensure the heat is not too intense to avoid damaging the module.

Cool the Cold Side:

Place an ice pack or pour cold water over the cold side to maintain the temperature difference.

Step 4: Connect Electrical Components

Connect Wires:

Attach insulated wires to the Peltier module’s output terminals.

Measure Output:

Connect the wires to a multimeter to measure the generated voltage (in volts) and current (in milliamps).

Power a Load:

Replace the multimeter with an LED, small motor, or another low-power device to observe the generator in action.

Step 5: Record Observations

Monitor Voltage and Current:

Note how the voltage and current vary with the temperature difference. Larger differences produce higher outputs.

Test Duration:

Measure how long the device can power the load as the temperature difference diminishes.

Optional Enhancements

Add Multiple Modules:

Wire several Peltier modules in series or parallel to increase voltage or current output.

Test Different Heat Sources:

Use a gas burner, solar heat, or other sources to observe differences in power generation.

Optimize Cooling:

Experiment with different cooling methods, such as running water, to improve efficiency.

Analysis

Thermoelectric Efficiency:

Calculate the efficiency by comparing the power output to the heat energy input (requires more advanced equipment).

Relationship to Temperature Difference:

Plot voltage vs. temperature difference to visualize the correlation.

Applications

Renewable Energy:

Understand how thermoelectric generators are used in waste heat recovery or off-grid power generation.

Practical Use:

Explore powering small devices with renewable thermal energy sources.

Observations

The experiment consistently produced a measurable voltage whenever a temperature gradient was applied. Over multiple trials, it was evident that the duration of useful power output depended not just on the initial temperature difference but also on the duration of cooling. Ice packs provided a strong but shorter effect. The LED was found to be an excellent qualitative indicator of performance, as changes in brightness were immediately visible to the naked eye.

Qualities of Thermoelectric Generators

Notable qualities of thermoelectric generators include:

Solid-state design with no moving parts, which allows for high reliability and silent operation.

Wide scalability: This form of technology can be implemented in a wide variety of different applications, suitable for a lot of different scenarios.

Suitability: This form of generator can be used in harsh environments such as space or remote monitoring stations.

Simple integration into existing systems using compact modules.

Maintenance-free operation over long lifetimes.

Economic and Environmental Factors

At small scales, thermoelectric generators are affordable, with modules costing only a few dollars. At larger scales, however, widespread adoption is limited by efficiency and material costs. Nevertheless, their application is still favorable in a lot of different conditions. Thermoelectric generators recover wasted energy, operate silently, and avoid the emissions and waste associated with conventional power systems.

In transport, integrating thermoelectric generators into vehicle exhausts could supplement electrical power, reducing fuel consumption. In the industry, they could offset electricity costs by capturing waste heat. The broader environmental impact includes reduced greenhouse gas emissions and improved energy efficiency, which aligns with carbon-neutral goals currently in place around the world.

Applications

Applications of TEGs include:

Automotive: Capturing exhaust waste heat to power onboard electronics.

Aerospace: Powering spacecraft through RTGs, as demonstrated by Voyager and Curiosity.

Wearable electronics: Harvesting body heat for sensors and smart fabrics.

Industrial sensors: Powering monitoring systems in harsh or remote environments.

Renewable integration: Geothermal plants and solar concentrators using TEGs.

Marine environments: Exploiting seawater-engine temperature differences.

Additionally, thermoelectric generators have been introduced to medical technology. For example, research is exploring whether implants could use body heat to power sensors that monitor patient health, removing the need for battery replacements. In architecture, prototype windows with embedded thermoelectric generators are being developed to harvest temperature differences between indoor and outdoor environments. Even in developing countries, low-cost thermoelectric generator stoves are being tested and trialed, which can enable families to cook meals while simultaneously charging mobile phones.

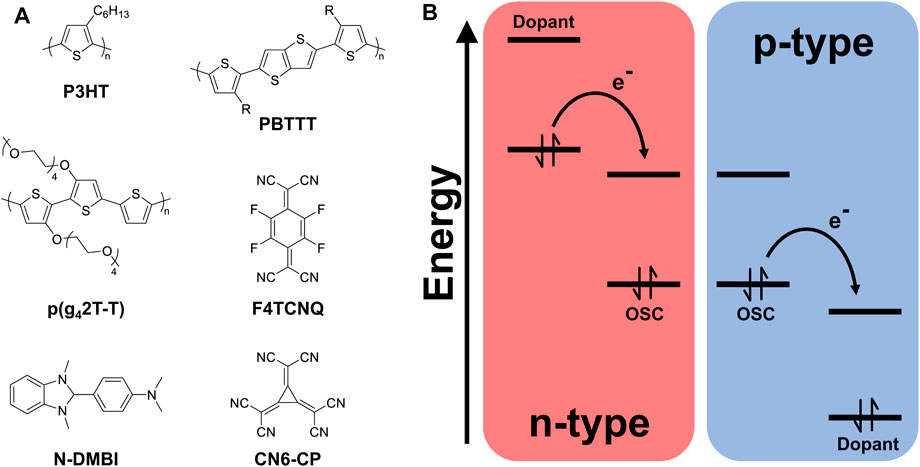

Chemical Properties and Structure

The most common thermoelectric material is bismuth telluride (Bi₂Te₃), commonly used for its high Seebeck coefficient and balanced conductivity. Alternative materials include skutterudites, half-Heusler alloys, and oxides, which show decent performance at higher temperatures. Structurally, thermoelectric generator modules consist of alternating p-type and n-type legs bonded to ceramic plates, ensuring thermal stability and electrical isolation. Heat flows through the module, while electrical current flows across the semiconductors, producing usable voltage.

Conclusion

This experiment demonstrates the potential and limitations of small-scale thermoelectric generators. The proportionality between temperature gradient and voltage was confirmed, and cooling methods have been proven to play a critical role in performance. The applications of thermoelectric generators cover educational demonstrations to real-world energy solutions across industries, transport, and space exploration. Ultimately, the experiment illustrates both the use cases and the current limitations of thermoelectric generators. While efficiency remains low compared to traditional generation methods, the advantages of solid-state reliability, compactness, and versatility should not be ignored. For us, this experiment is a useful demonstration that complex scientific principles can be made tangible with simple, safe, and affordable setups

Although current modules remain limited by material efficiency, research progress continues to improve it. For students, engineers, and scientists, thermoelectric generators represent how a mixture of physics, materials science, and sustainable energy technology can impact the world around us. This experiment not only provided a clear visual demonstration of energy conversion but also underlined the role of innovation in tackling global energy challenges.

Comments